MISL Engineering

Over 40 years experiance MISL are precision engineers based in Basingstoke, Hampshire.

Finding the best CNC Engineers to deal with can be a challenge as knowing just how to get the best solution is vital. With a wealth of experience at MISL spanning 40+ years, our team of highly trained and qualified engineers specialise in the manufacturing of bespoke products for a variety of commercial, industrial and domestic clients.

We can offer the following services, CNC Manufacturing (Milling and Turning), Component Part design, CAD Development, CAM processing, 3D CNC Machining, Electronic Circuit Design, PCB Development, ARM MCU Programming, Precision Sensor Monitoring

About MISL Engineering

We are precision mechanical engineers with over 40 years engineering experience including aerospace and motorsport industries.

We have the latest CAD systems for 3D component part modelling part manufacturing on our HAAS CNC machine tools. Fully proficient in 3D part program machining, G-Code development, machine tool control, setting and operation. In motorsport we are associated with Hawke Motorsport and a member of The International Guild of Specialist Engineers TIGOSE supporting Classic Car renovation and specialised component part replacement programme using our Prototyping “One Off” price promise.

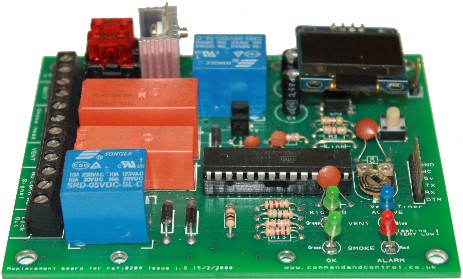

In electronics, we have our own dedicated laboratory for device design development & testing with electronic simulation and PCB track layout applications, with many file importing and exporting standards and full signal analysis digital storage oscilloscope and communications protocol analyser. We are proficient in programming for K20 ARM Micro Controller Unit (MCU). We can analyse practically any communications protocol and create bespoke developments for any web based device development interfacing with machine tool for shop floor distribution and specialised sensor monitoring.

Automotive Part Manufacture

We are specialists in the manufacture of automotive components; we belong to TIGOSE The International Guild of Specialist Engineerss for automotive part re-engineered parts. We are associated with MotorSport companies with direct access to their engineering expertise in terms of body part and mechanical speed and efficiency. Working with our Motorsport partners, we have developed a detailed appreciation of the automotive industry’s rapid manufacturing needs. Our aim is to fully understand what you want to achieve. We then provide expert advice and project management to ensure your expectations are met. We keep pace with innovative materials and manufacturing techniques. We can provide everything necessary to produce any part under the bonnet. When it comes to lightweight, fuel efficient and high performance automotive parts, use our expertise to realise your desired outcome.

Electronics Development

In electronics, we have our own dedicated laboratory for device design development & testing with electronic simulation and PCB track layout applications, with many file importing and exporting standards and full signal analysis digital storage oscilloscope and communications protocol analyser. We are proficient in programming for K20 ARM Micro Controller Unit (MCU). We can analyse practically any communications protocol and create bespoke developments for any web based device development interfacing with machine tool for shop floor distribution and specialised sensor monitoring.

Design and manufacture our own engineered products, which include:

- Motorsports parts

- Load Cell devices

- Multi storey fire alarm vent controllers

- CNC workshop control panels

- CNC spindle speed controllers

- Our own 3 Axis CNC controller

MISL Services

Rapid Parts for Designers

For many design consultancies, the advantage of using rapid

manufacturing is that you don’t always need to know exactly what you need. We

want to understand your design and its intended application. We will then

recommend the most suitable materials and techniques for the manufacture of a

prototype.

Allow MISL to be your trusted rapid manufacturing partner. We’ll help

you from concept design, through to full production.

Low Volume Production

Historically, costs and time implications associated with low volume

production often outweighed the value of the end product. With advances in

rapid manufacturing this is no longer the case.

With an established network of production partners, FRP’s services

include the low volume manufacturing of production parts. Limited production

may be all that is required, or you could need a small run for manual assembly

prior to upscaling to full production. Either way, we have the expertise to

deliver the optimum solution.

Manufacturing for Design Consultancies

Rapid manufacturing plays a vital role in convincing your clients to invest in your designs. A prototype can prove the structural integrity of your design or show a fully representative example. It allows the client to handle trial or appreciate your work, prior to the finished design being created. Using our prototyping approach will allow fast and cost effective parts manufactured for your demonstration.

The ability to provide you with a Rapid Manufacturing option in the design process can make all the difference when it comes to persuading clients, investors or focus groups. From one-off architectural design, to product design and mass produced packaging. As an independent supplier, we offer the best option to satisfy your requirements. We can determine a Manufacture Process Optimisation ensuring machining feasibility consistency of dimensions from concept to production.

Our approach, supported by our development process, makes it quick and cost effective to make design modifications.

Specialist Partners

As independent providers, with an established network of production partners, MISL selects the best specialists to undertake your project. We will communicate your exacting requirements and take responsibility for managing the process, from start to finish.

Transforming Ideas into Solutions

From the design stage, we can verify the feasibility, application, technical requirements. Our input can be invaluable in design modifications that help minimise the risk of costly and time consuming anomalies.

Full Production

We offer full machining production volumes to the same

exacting standards. We offer high volume manufacturing services for highly

regulated markets, including medical components and integrated electronic devices

"We are very happy to keep using MISL as they have always provided a fantastic service and produce a great quality product"

"MISL service and commitment to the customer need is second to none"

"We particularly like the priority service MISL offer, this has got us out of some sticky situations"

"MISL's industry understanding and experience actually saved us money, Paul explained with a few tweeks to the design it would save us money and it did!!"

Where to find us

Management Innovation Services Ltd

Unit 5 Templar Court

Hampshire

RG21 6AB

TEL : 01256 470 281

Quote Request & Contact

Quote Request and Contact

Do you need a confidential manufacturing quotation?

Upload your drawing or NDA using the form on this page, we will maintain any confidentiality you need.

We would suggest a PDF file format for confidential information.

You can of course use the info@misl.uk.com email or call us directly on 01256 470281 if you prefer a more direct path.

File Types accepted are .PDF.DWG .IGES .STEP.DXF

Our Working hours are:

Mon - 9AM - 5.30PM

Tue - 9AM - 5.30PM

Wed - 2PM - 10PM

Thu - 9AM - 5.30PM

Fri - 9AM - 5.30PM

Weekends - Closed